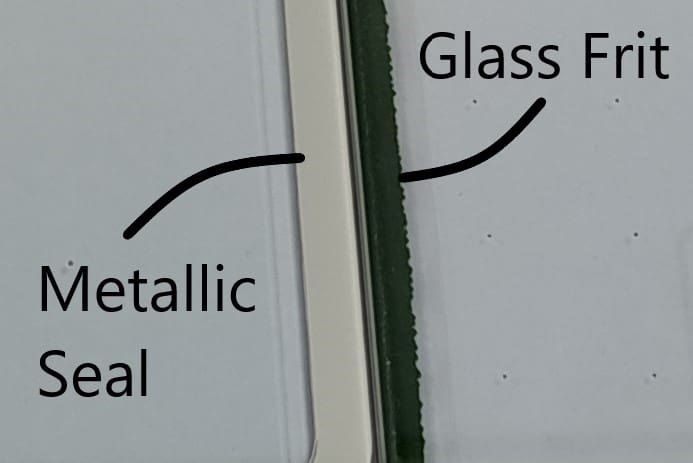

Why a Metallic Edge Seal in Vacuum Insulated Glass Units is Superior to a Glass Frit Edge Seal

The edge seal in vacuum insulated glass (VIG) units plays a critical role in maintaining the vacuum and ensuring the […]

The edge seal in vacuum insulated glass (VIG) units plays a critical role in maintaining the vacuum and ensuring the unit’s longevity and performance. Traditionally, glass frit edge seals have been used, but metallic edge seals are increasingly seen as a superior alternative. Here’s why metallic edge seals offer significant advantages over glass frit edge seals in VIG units:

1. Durability and Mechanical Strength of Edge Seal in Vacuum Glass

Metallic Edge Seals:

- High Mechanical Strength: Metallic edge seals typically consist of materials like stainless steel, which possess high tensile strength and are resistant to mechanical stresses. This makes them less likely to crack or fail under pressure or thermal expansion and contraction.

- Flexibility: Metals can flex slightly under stress without breaking, accommodating minor movements and stresses in the glass without compromising the seal.

Glass Frit Edge Seals:

- Brittleness: Glass frit, while strong, is brittle and more susceptible to cracking under mechanical stress or thermal cycling. This brittleness can lead to premature failure of the edge seal in vacuum units.

- Less Flexibility: Glass does not flex; it can only withstand a limited amount of stress before it fractures. This makes glass frit seals more vulnerable to breaking under stress.

2. Thermal Stability of Edge Seal in Vacuum Glass

Metallic Edge Seal in Vacuum Units:

- High Thermal Conductivity: Metals like stainless steel have higher thermal conductivity, allowing them to better distribute heat and reduce the risk of thermal stress concentrations.

- Wide Operating Temperature Range: Metallic seals can withstand a broader range of temperatures, making them suitable for environments with significant temperature variations.

Glass Frit Edge Seal in Vacuum Units:

- Thermal Expansion Mismatch: Glass frit has a different thermal expansion coefficient compared to the glass panes it seals. This mismatch can create stress points during temperature changes, leading to seal failure.

- Limited Temperature Tolerance: Glass frit seals are more prone to thermal shock and may not perform well under extreme temperature conditions.

3. Vacuum Retention of Edge Seal in Vacuum Glass

Metallic Edge Seals:

- Superior Vacuum Integrity: Metallic seals provide an excellent barrier against gas permeation, ensuring long-term vacuum retention within the VIG unit.

- Lower Permeability: Metals generally have lower permeability to gases compared to glass, resulting in better long-term maintenance of the vacuum.

Glass Frit Edge Seals:

- Potential for Micro-Leaks: Glass frit seals can develop micro-cracks over time. This may allow gases to slowly permeate and degrade the vacuum.

- Higher Permeability: Glass, even when fused, can have higher permeability to gases, which can compromise the vacuum over time.

4. Manufacturing and Quality Control

Metallic Edge Seals:

- Precision Manufacturing: Metallic seals can be manufactured with high precision, ensuring consistent quality and performance. Advanced welding and brazing techniques allow for strong, consistent seals.

- Ease of Quality Control: The metallic edge seal manufacturing process allows for better quality control and testing, ensuring each unit meets stringent performance standards.

Glass Frit Edge Seals:

- Complex Manufacturing Process: The process of creating glass frit seals is more complex and can result in variations in seal quality. Ensuring uniformity and strength across all units can be challenging.

- Difficult to Inspect: Detecting flaws in glass frit edge seal in vacuum units can be more difficult. This potentially leads to undetected weaknesses.

Conclusion While both metallic and glass frit edge seals are used in VIG units, metallic edge seals offer significant advantages in terms of durability, thermal stability, vacuum retention, and manufacturing consistency. These benefits make metallic edge seal in vacuum units a superior choice for ensuring the long-term performance and reliability of vacuum insulated glass units. As a result, many modern VIG manufacturers are adopting metallic edge seals to enhance the quality and lifespan of their products.