Decoding Vacuum Insulated Glazing

Discover the science behind vacuum insulated glazing (VIG) and its remarkable thermal performance. Explore how the vacuum gap between glass panes minimises heat transfer, enhances energy efficiency, and revolutionises building design. Learn about the advancements in low-emissivity coatings and spacer materials, and the potential of VIG to create sustainable living environments.

Understanding the Science Behind Vacuum Insulated Glazing and Its Thermal Performance

Vacuum Insulated Glazing (VIG) is a revolutionary technology that offers exceptional thermal performance compared to traditional glazing systems. By utilising a vacuum cavity between two or more glass panes, VIG significantly reduces heat transfer through conduction, convection, and radiation. This article explores the structure and components of VIG, its benefits over traditional glazing systems, and the science behind its thermal performance.

In the section “Understanding Vacuum Insulated Glazing,” we delve into the structure and components of VIG. We explain how VIG consists of low-iron float glass panes, a spacer and sealing mechanism, and a vacuum cavity. These components work together to provide structural integrity, excellent thermal insulation, enhanced sound insulation, and reduced condensation.

The subsequent section, “The Science Behind Thermal Performance,” delves into the heat transfer mechanisms in glazing systems and the role of the vacuum cavity in reducing heat transfer. We explore conduction, convection, and radiation as the primary modes of heat transfer and explain how VIG eliminates or minimises these mechanisms, resulting in superior thermal insulation.

Moving forward, we discuss the factors that affect the thermal performance of VIG in the section “Factors Affecting Thermal Performance of VIG.” We highlight the importance of the vacuum seal quality, spacer material and design, glass thickness and properties, coatings, and low-emissivity layers. Additionally, we emphasise the impact of external factors like temperature and atmospheric pressure on the performance of VIG.

Next, we explore the evaluation of thermal performance in glazing systems, including VIG, in the section “Evaluating Thermal Performance.” We explain the concepts of U-value and R-value as measurements used to assess thermal insulation. We discuss the measurement and calculation methods involved in determining these values and the energy efficiency considerations that come into play.

Finally, we examine the diverse applications of Vacuum Insulated Glazing in residential buildings, commercial and office buildings, as well as historical preservation and restoration projects. We highlight how VIG improves energy efficiency, enhances occupant comfort, and preserves architectural integrity in various settings.

By understanding the science behind Vacuum Insulated Glazing and its thermal performance, architects, designers, and building owners can make informed decisions to maximize energy efficiency, improve thermal insulation, and create aesthetically pleasing environments.

II. Understanding Vacuum Insulated Glazing

A. Explanation of the structure and components of VIG

1. Glass panes:

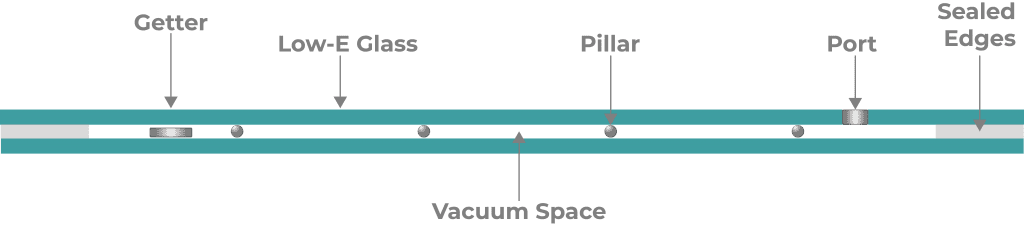

Vacuum Insulated Glazing (VIG) consists of two or more glass panes separated by a vacuum cavity. These glass panes are typically made of low-iron float glass to maximise transparency and minimise colour distortion. The glass panes play a crucial role in providing structural integrity to the VIG unit while allowing visible light to pass through.

2. Spacer and sealing:

A spacer is used to maintain the separation between the glass panes and create the vacuum cavity. It is typically made of materials with low thermal conductivity, such as stainless steel or aluminum, to minimise heat transfer across the edges of the glass panes. The spacer also serves as a structural support and helps to maintain the uniform distance between the glass panes. The edges of the glass panes are sealed using hermetic sealing techniques to create an airtight enclosure.

3. Vacuum cavity:

The vacuum cavity, also known as the interpane or interstitial space, is the region between the glass panes where the air is evacuated to create a vacuum. This vacuum cavity is crucial for improving the thermal performance of the glazing system. By removing the air molecules and creating a vacuum, heat transfer through conduction and convection is significantly reduced. The vacuum cavity is typically maintained at a pressure below 0.1 Pa (Pascal) to ensure optimal thermal insulation.

B. Benefits of VIG over traditional glazing systems

1. Improved thermal insulation:

Vacuum Insulated Glazing offers superior thermal insulation compared to traditional glazing systems. The vacuum cavity eliminates convective heat transfer by removing air, which is an efficient conductor of heat. Additionally, the low thermal conductivity of the spacer materials minimises conductive heat transfer. As a result, VIG can significantly reduce heat loss or gain through windows, leading to improved energy efficiency and better thermal comfort in buildings.

2. Enhanced sound insulation:

The vacuum cavity in VIG also provides excellent sound insulation properties. Sound waves are dampened as they travel through the vacuum, reducing noise transmission. This makes VIG particularly beneficial in areas with high noise pollution, such as urban environments or near transportation routes. The enhanced sound insulation helps create quieter and more comfortable indoor spaces.

3. Reduced condensation:

Vacuum Insulated Glazing minimises the occurrence of condensation on the interior glass pane. The vacuum cavity eliminates the presence of moisture-laden air, reducing the likelihood of condensation forming on the cold surface of the inner pane. This is particularly advantageous in cold climates or environments with high humidity, as it helps maintain clear views and prevents potential damage to the glazing unit.

4. Design flexibility:

VIG offers design flexibility due to its slim profile. The thin construction of the glazing unit, typically around 8mm, allows for sleek and aesthetically pleasing window designs. This slim profile is especially advantageous for heritage windows and buildings where maintaining the original appearance is crucial. Vacuum glazing can effectively emulate the appearance of single glazing, making it an ideal choice for projects that require compliance with planning permission or preservation guidelines for listed buildings.

By utilising VIG, architects and designers can enhance the thermal efficiency of heritage windows while preserving their authentic look. This not only helps maintain the historical value and architectural integrity of the building but also ensures compliance with regulations for heritage preservation.

Moreover, the design versatility of VIG enables architects and designers to incorporate larger glazed areas, maximising the penetration of natural light into interior spaces. The visually appealing building facades created with VIG can provide occupants with a connection to the outdoors, creating a more pleasant and inviting environment. The combination of excellent thermal performance and design flexibility makes Vacuum Insulated Glazing a preferred choice for both modern and heritage architectural projects.

III. The Science Behind Thermal Performance

A. Heat transfer mechanisms in glazing systems

1. Conduction:

Conduction is the transfer of heat through direct contact between materials with different temperatures. In glazing systems, conduction occurs when heat flows through the glass and other components of the unit. Traditional glazing systems with air or gas-filled cavities allow conduction to take place as the molecules within the cavity can transfer heat. However, in Vacuum Insulated Glazing (VIG), the presence of a vacuum cavity significantly reduces conduction by eliminating the molecules that would otherwise carry heat.

2. Convection:

Convection involves the transfer of heat through the movement of fluids or gases. In traditional glazing systems, air or gas-filled cavities allow convection currents to form, leading to heat transfer. The circulating air or gas molecules carry heat from the warm side to the cold side, compromising the overall thermal performance. In VIG, the vacuum cavity eliminates convection by removing the fluid medium, thereby preventing heat transfer through this mechanism.

3. Radiation:

Radiation is the transfer of heat through electromagnetic waves. In glazing systems, radiation occurs when heat energy is emitted by one surface and absorbed by another. Traditional glazing systems can experience significant radiative heat transfer, especially if the glass surfaces have low emissivity. However, in VIG, the vacuum cavity plays a role in reducing radiative heat transfer. With no air or gas molecules to facilitate radiation, the vacuum cavity helps minimise the exchange of heat between the glass panes, improving the overall thermal insulation.

B. Role of the vacuum cavity in reducing heat transfer

1. Elimination of convective heat transfer:

The vacuum cavity in VIG eliminates the presence of air or gas molecules, preventing convective heat transfer. Without fluid mediums to carry heat, the vacuum cavity disrupts the formation of convection currents and minimises heat transfer through this mechanism. This elimination of convective heat transfer significantly improves the thermal performance of VIG compared to traditional glazing systems.

2. Minimisation of conductive heat transfer:

The vacuum cavity also plays a crucial role in reducing conductive heat transfer. By removing the air or gas molecules within the cavity, VIG effectively eliminates the material that would otherwise conduct heat between the glass panes. This minimisation of conductive heat transfer helps maintain a thermal barrier, reducing the heat flow through the glazing unit and improving its insulation properties.

3. Reduction of radiative heat transfer:

Radiative heat transfer is also reduced in VIG due to the vacuum cavity. With no air or gas molecules present, the vacuum acts as a barrier that inhibits the exchange of heat through radiation between the glass panes. This reduction in radiative heat transfer enhances the overall thermal insulation of VIG, resulting in improved energy efficiency and better temperature regulation within the building.

Understanding the science behind thermal performance in glazing systems helps us appreciate the specific role that the vacuum cavity plays in reducing heat transfer. By eliminating convective heat transfer, minimising conductive heat transfer, and reducing radiative heat transfer, Vacuum Insulated Glazing achieves superior thermal insulation compared to traditional glazing systems.

By understanding the structure and components of Vacuum Insulated Glazing, as well as its benefits over traditional glazing systems, we can appreciate the significance of this technology in achieving improved thermal performance, enhanced sound insulation, reduced condensation, and design flexibility in buildings.

IV. Factors Affecting Thermal Performance of VIG

A. Quality of the vacuum seal:

The quality of the vacuum seal in Vacuum Insulated Glazing (VIG) is critical for its thermal performance. A proper and durable vacuum seal ensures that the vacuum cavity remains airtight over an extended period. Flexible edge seals are commonly used to make the seals reliable. These flexible seals accommodate the differential thermal expansion and contraction between the glass panes, ensuring a tight and consistent seal even under varying temperatures. By utilising flexible edge seals, the integrity of the vacuum seal is maintained, minimising the potential for leakage or loss of vacuum and optimising the thermal performance of VIG.

B. Spacer material and design:

The spacer material and design used in VIG significantly impact its thermal performance. The spacer separates the glass panes and helps maintain the distance between them. The choice of spacer material plays a crucial role in minimizing conductive heat transfer. Materials with low thermal conductivity, such as stainless steel or aluminum, are commonly used. The design of the spacer can also affect the overall thermal performance by influencing the size and shape of the vacuum cavity and the structural integrity of the glazing unit.

C. Glass thickness and properties:

The thickness and properties of the glass panes used in VIG influence its thermal performance. Thicker glass panes generally provide better insulation due to their higher resistance to heat transfer. Low-iron float glass is often used in VIG to maximise transparency and reduce color distortion. Additionally, certain glass properties, such as low emissivity (low-e) coatings, can further enhance the thermal insulation by minimising radiative heat transfer. These coatings reduce the amount of heat radiated from the warm side to the cold side of the glazing unit.

D. Coatings and low-emissivity (low-e) layers:

Coatings and low-emissivity (low-e) layers can significantly impact the thermal performance of VIG. Low-e coatings are designed to reflect a significant portion of the infrared heat radiation, keeping the heat inside during the winter and reflecting it back during the summer. These coatings can help reduce radiative heat transfer, improving the overall energy efficiency of the glazing unit. The selection and quality of coatings or low-e layers should be carefully considered to optimise the thermal performance of VIG.

E. External factors like temperature and atmospheric pressure:

External factors, such as temperature and atmospheric pressure, can affect the thermal performance of VIG. Temperature variations can cause expansion and contraction of the materials in the glazing unit, potentially affecting the vacuum seal integrity and thermal insulation. Changes in atmospheric pressure can also impact the performance of the vacuum cavity. Proper installation, suitable materials, and design considerations should account for these external factors to ensure the long-term thermal efficiency of VIG.

By considering and optimising the factors affecting thermal performance, including the quality of the vacuum seal, spacer material and design, glass thickness and properties, coatings and low-e layers, as well as external factors like temperature and atmospheric pressure, the overall thermal insulation and energy efficiency of Vacuum Insulated Glazing can be maximised.

V. Evaluating Thermal Performance

A. U-value and R-value in glazing systems:

The thermal performance of glazing systems, including Vacuum Insulated Glazing (VIG), is often evaluated using U-value and R-value measurements.

1. U-value:

The U-value, also known as the thermal transmittance, represents the rate of heat transfer through a material or assembly. In glazing systems, including VIG, a lower U-value indicates better insulation properties. It quantifies the amount of heat that can pass through the glazing unit, considering all modes of heat transfer, such as conduction, convection, and radiation. Therefore, a lower U-value signifies higher thermal insulation and improved energy efficiency.

2. R-value:

The R-value is the reciprocal of the U-value and represents the thermal resistance of a material or assembly. A higher R-value indicates better insulation. The R-value is calculated by dividing the thickness of the material or assembly by its U-value. It provides a simplified representation of the insulation properties, where higher values signify greater resistance to heat transfer.

More about U-Values and R-Values: https://indowwindows.com/resources/blog/r-value-vs-u-value/

B. Measurement and calculation methods:

Evaluating the thermal performance of VIG involves both measurement and calculation methods to determine the U-value and R-value.

1. Measurement methods:

Specialised testing facilities can measure the U-value of glazing systems, including VIG, using standardised procedures such as ASTM C1363 or ISO 12567. These methods involve subjecting the glazing unit to controlled temperature differences and measuring the heat flux across the sample. These measurements provide accurate data on the thermal performance of VIG under specific conditions.

2. Calculation methods:

Thermal performance calculations can estimate the U-value and R-value of VIG based on the properties of its components. These calculations consider factors such as the thermal conductivity of the glass panes, spacer material, and coatings, as well as the dimensions and thicknesses of these components. Software tools, such as energy modelling software, can aid in performing these calculations and provide valuable insights into the expected thermal performance of VIG in various scenarios.

C. Energy efficiency considerations:

When evaluating the thermal performance of VIG or any glazing system, it is essential to consider energy efficiency as a key factor.

1. Heating and cooling loads:

The thermal performance of glazing systems directly impacts the heating and cooling loads of a building. A high-performance glazing system, such as VIG with low U-values, reduces heat transfer through windows, resulting in reduced energy consumption for heating and cooling. This can lead to energy savings and increased comfort for building occupants.

2. Overall building energy efficiency:

The thermal performance of glazing systems, when combined with other building envelope elements and insulation, plays a significant role in the overall energy efficiency of a building. By selecting and implementing VIG with excellent thermal insulation properties, the overall energy efficiency of the building can be improved, reducing the reliance on mechanical heating and cooling systems and lowering carbon emissions.

3. Sustainable building certifications:

Many sustainable building certification programs, such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method), consider the thermal performance of glazing systems when assessing the environmental impact and energy efficiency of buildings. Choosing VIG with superior thermal performance can contribute to achieving these certifications and demonstrating a commitment to sustainability.

When evaluating the thermal performance of VIG, understanding the concepts of U-value and R-value, utilising appropriate measurement and calculation methods, and considering energy efficiency aspects are crucial for selecting and optimizing the glazing system for improved thermal insulation and energy efficiency in buildings.

VI. Applications of Vacuum Insulated Glazing

A. Residential buildings:

Vacuum Insulated Glazing (VIG) finds wide application in residential buildings, offering numerous benefits to homeowners. Its superior thermal insulation properties help reduce heat loss or gain through windows, resulting in improved energy efficiency and increased comfort. VIG windows can contribute to reducing energy consumption for heating and cooling, leading to lower utility bills. Additionally, the slim profile and sleek design of VIG windows enhance the aesthetic appeal of residential buildings, allowing for larger glazed areas and maximising natural light penetration.

B. Commercial and office buildings:

VIG is well-suited for commercial and office buildings, where energy efficiency and occupant comfort are paramount. The excellent thermal insulation properties of VIG contribute to reduced heating and cooling loads, enabling more sustainable and cost-effective building operations. By minimising heat transfer through windows, VIG helps maintain consistent indoor temperatures, reducing the reliance on heating systems and enhancing occupant comfort. Furthermore, the aesthetic versatility of VIG allows architects and designers to create visually appealing facades and open-plan office spaces with abundant natural light.

C. Historical preservation and restoration projects:

Vacuum Insulated Glazing plays a vital role in historical preservation and restoration projects, where maintaining the original aesthetic and improving energy efficiency are key considerations. VIG offers a solution for improving the thermal performance of windows in historic buildings without compromising their architectural integrity. With its slim profile, VIG can emulate the appearance of single glazing, making it an ideal choice to meet planning permission requirements for heritage windows. By replacing old and inefficient glazing systems with VIG, historical buildings can benefit from enhanced energy efficiency while preserving their unique architectural character.

D. Specialty applications (e.g., museums, laboratories):

Speciality applications, such as museums and laboratories, often require stringent environmental control and protection of valuable artefacts or sensitive experiments. Vacuum Insulated Glazing meets these requirements by providing exceptional thermal insulation and sound reduction properties. The reduced heat transfer and minimal condensation risk in VIG windows create a stable indoor environment, vital for preserving delicate artworks, artefacts, or conducting precise scientific experiments.

The applications of Vacuum Insulated Glazing extend across various sectors, including residential buildings, commercial and office buildings, historical preservation and restoration projects, as well as speciality applications like museums and laboratories. Its superior thermal insulation, aesthetic versatility, and energy efficiency benefits make VIG a desirable choice for diverse architectural projects seeking optimal comfort, sustainability, and preservation of valuable assets.

VII. Current Advancements and Future Trends

A. Innovations in VIG technology:

Vacuum Insulated Glazing (VIG) continues to evolve with ongoing innovations aimed at improving its performance and expanding its applications. Some current advancements include:

1. Enhanced vacuum seal technology:

Researchers and manufacturers are developing improved vacuum seal materials and techniques to enhance the durability and longevity of VIG. These advancements aim to minimise the risk of vacuum loss over time, ensuring long-term thermal performance.

2. Thinner profiles:

Efforts are underway to reduce the thickness of VIG units while maintaining their thermal insulation properties. Thinner profiles allow for easier integration into existing window frames and enable the use of VIG in retrofit applications.

3. Novel spacer materials:

Researchers are exploring alternative spacer materials with even lower thermal conductivity. These advancements aim to further reduce heat transfer through the spacer, enhancing the overall thermal insulation of VIG.

C. Potential for sustainable design and energy conservation:

Vacuum Insulated Glazing holds significant potential for sustainable design and energy conservation in buildings, including its contribution towards passive house builds. As the focus on reducing energy consumption and carbon emissions intensifies, VIG can play a crucial role in achieving energy-efficient building envelopes. Its exceptional thermal insulation properties can substantially reduce heating and cooling demands, making it an ideal choice for passive house construction. Passive houses aim to minimise energy usage by relying on efficient building design, insulation, and ventilation strategies. By incorporating VIG windows into passive house designs, the overall thermal performance of the building envelope can be significantly improved. The high thermal resistance of VIG helps maintain stable indoor temperatures, reducing the need for active heating or cooling systems. This not only reduces energy consumption but also enhances occupant comfort. Furthermore, when combined with renewable energy sources, such as solar panels, VIG windows can contribute to net-zero or energy-positive buildings, further advancing sustainable design and energy conservation efforts.

By continually pushing the boundaries of VIG technology, exploring integration with smart building systems, and harnessing its potential for sustainable design and energy conservation, the future of Vacuum Insulated Glazing holds promise for creating more energy-efficient and environmentally conscious buildings.

Conclusion

In conclusion, vacuum insulated glazing (VIG) stands as a remarkable technological advancement in the field of thermal performance. By harnessing the power of a vacuum gap between glass panes, VIG provides enhanced insulation capabilities, significantly reducing heat transfer and improving energy efficiency in buildings.

Throughout this discussion, we have explored the underlying science behind VIG and its thermal performance. We have seen how the vacuum gap acts as an efficient barrier against heat transfer through conduction, convection, and radiation, thereby minimising thermal losses. This unique design allows VIG to outperform traditional double-glazed windows and offers a promising solution for addressing energy consumption and environmental concerns.

Furthermore, the development of low-emissivity coatings and advanced spacer materials has further improved the thermal performance of VIG, making it an increasingly attractive option for architects, engineers, and homeowners seeking sustainable building solutions.

While VIG presents numerous advantages, it is important to note that its production costs and complexity are currently higher compared to conventional glazing. As technology continues to evolve and mass production methods improve, it is anticipated that VIG will become more affordable and widely accessible.

In summary, vacuum insulated glazing offers a fascinating glimpse into the world of cutting-edge glass technology and its potential to revolutionise energy-efficient building design. With its superior thermal performance and ability to reduce heating and cooling costs, VIG holds tremendous promise for creating sustainable and comfortable living environments in the future.

Explore LandVac Optimum Vacuum Glazing here.