LandVac Double Glazing by LandGlass

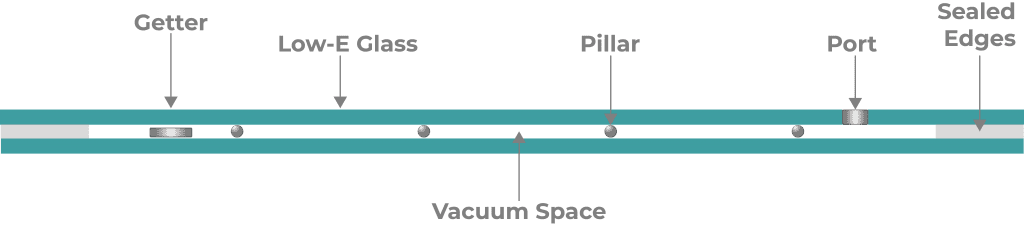

LandVac is a superior glazing unit that has been designed and manufactured by LandGlass. It has been created with a unique combination of advanced technology and innovative design. The product is made up of two flat tempered glass panes that are separated by micro support pillars, sealed around the edges, and formed with a vacuum chamber in the cavity. This vacuum chamber is what makes LandVac stand out from other traditional double glazing units. The vacuum acts as an insulating layer, reducing heat transfer and providing exceptional thermal performance.

The vacuum chamber also acts as a barrier to prevent moisture and gas from entering the cavity, ensuring that the insulation performance of the glazing remains consistent over time. The use of tempered glass also provides exceptional strength, durability and safety, making LandVac suitable for a wide range of applications. These features make LandVac a unique and innovative product, offering outstanding energy efficiency and durability, as well as superior acoustic and environmental performance.

Benefits of Vacuum Glazing

Beautiful.

Ultra-thin profile makes this perfect for conservation projects.

Warm.

Centre-pane U-values of 0.4W/m2K and superior G-values.

Quiet.

Leading acoustic performance, without the need for thicker, heavier panes of glass.

Safe.

The LandVac unit is constructed from two panes of 4mm toughened glass.

Reliable

Industry leading 15-year warranties and an anticipated lifespan in excess of 25 years.

Sustainable

The units are fully recyclable and have no noble gasses which are energy intensive to produce.

Who are LandGlass?

LandGlass was founded in 1999 and specialises in the R&D, manufacture and sale of glass tempering furnaces and technology.

LandGlass saw the emergence of vacuum glazing technology and noted the difficulty that current suppliers were having with combining toughened glazing and vacuum cavities. Utilising their expertise of tempered glass production, they were able to develop a truly innovative product which delivered the safety characteristics of a toughened glass unit, while also providing the considerable performance benefits of a vacuum cavity. Further to this, the 4mm toughened glass used in all LandVac units gives additional strength and requires 10 times fewer micro-pillars in the cavity when compared to all other vacuum glazing units on the market.

LandGlass built a unique automated VIG production line which is about 500 metres long and boasts an annual capacity of 120,000m2 of vacuum glazing units. LandGlass is a flexible and dynamic business that can offer a huge range of sizes (the maximum size is 1500mm × 2500mm and the minimum size is 300mm × 300mm), a variety of shapes at a reasonable cost and are continually working on improving the product in terms of appearance and performance. They are an excellent partner for Vacuum Glazing UK Ltd. and we are proud to promote their products in the UK market.

LandVac Specification

LandVac Heritage Vacuum Insulated Glass

LandVac Heritage vacuum glazing has a number of benefits that can improve the efficiency and performance of the windows in a period property. Benefits include:

- Fully tempered LandVac is a fully tempered vacuum insulated glass. LandVac retains the safety features of tempered glass against impact. The surface stress of any position in LandVac tempered vacuum insulated glass exceeds 90MPa.

- Energy Savings The thermal insulation performance of LandVac is 2 to 4 times better than insulated glass due to its’ high vacuum interspace that eliminates any gas heat transfer. By using high-performance Low-E coating, it also considerably suppresses radiation heat transfer and reduces the U-value of LandVac Heritage to 0.4 W/(m2K).

- Longevity The life expectancy of LandVac exceeds 25 years. The flexible edge sealing materials avoid the sealing failure caused by the brittle edge sealing material. With the assistance of built-in high-efficiency getters, LandVac can sustain its superior performance against harsh environments and material ageing for many years.

- Eliminates internal condensation The high vacuum interspace of LandVac effectively eliminates the dew condensation phenomenon, while the outstanding thermal insulation performance ensures interior glass surface free of condensation even when the outdoor temperature falls to -40 ℃. Please see this article regarding all forms of condensation on Vacuum Insulation glass.

- Noise reduction The high vacuum interspace of LandVac effectively blocks sound transmission. For every 5 dB of noise increase, the effect on auditory experiences differs by 3 to 4 times. The weighted sound insulation measurement indicates that an outdoor noise level of 75 dB, can be reduced by 41 dB with LandVac, while the typical reduction by regular laminated glass is only 29 dB. It has a remarkable soundproofing effect against medium and low frequency noise such as traffic and construction noise.

- Flexibility Factors such as geographical location, elevation, and installation angle do not affect the performance of LandVac. Thanks to the high vacuum interspace of LandVac, there is no thermal expansion or contraction even if the elevation of the location where it’s used is significantly different from where it’s manufactured. The heat transfer coefficient of LandVac remains constant regardless of whether it’s mounted horizontally or with an angle, making it suitable for energy efficient roofing or slope installation.