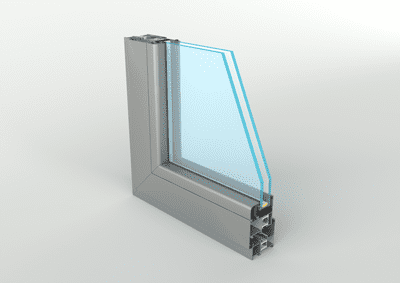

Embrace the Future of Architectural Design with LandVac Vacuum Glazing

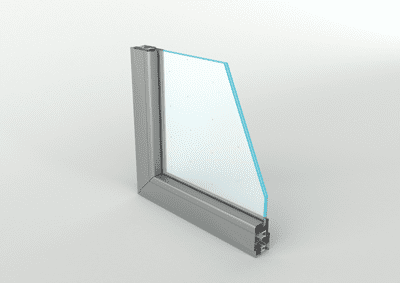

Welcome to the Architects page, where we explore the innovative applications of LandVac vacuum glazing in architectural design. Discover how LandVac can enhance your projects with its cutting-edge technology and exceptional energy efficiency.

Get a Quote